About our works #1: Construction support for complex shapes

What does Syntegrate do?

Even within the architecture and construction industry, not much is known about what we do. It is also very difficult to explain to people outside the industry. Our skills and the software we use varies, and we are often surprised by the work the person next to us is doing in the company. I would like to write about what kind of work Syntegrate does in as simple as possible.

Construction support for complex shapes

One of our specialties is to support the construction of complex shapes. Let’s find out what Syntegrate does through one of the buildings we completed.

0.Design

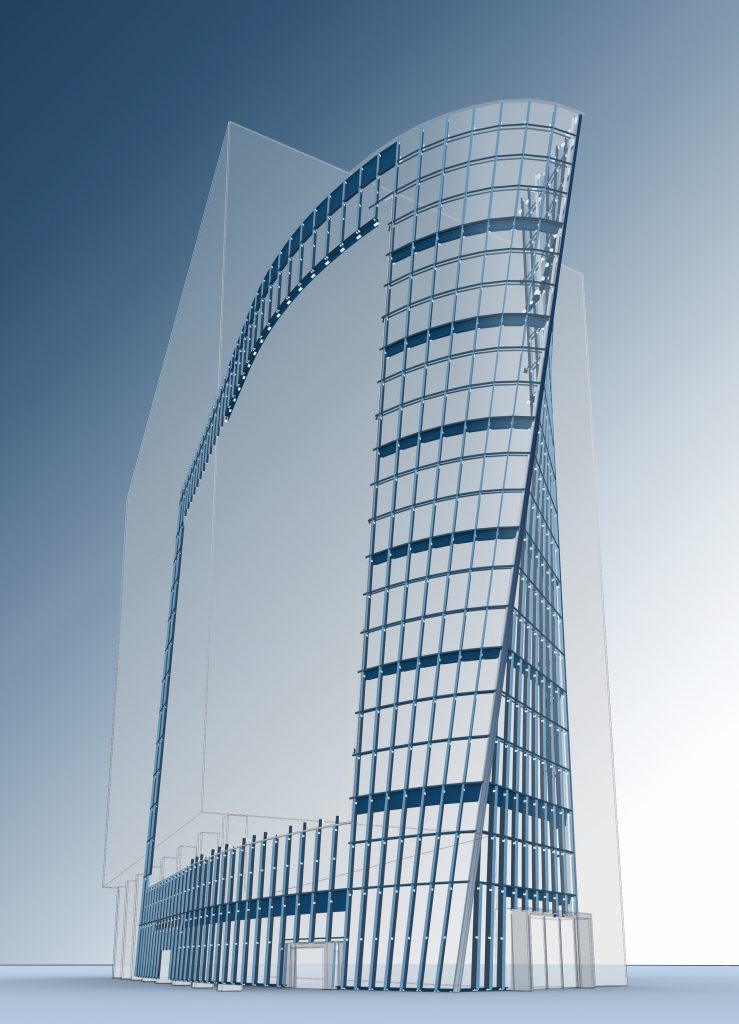

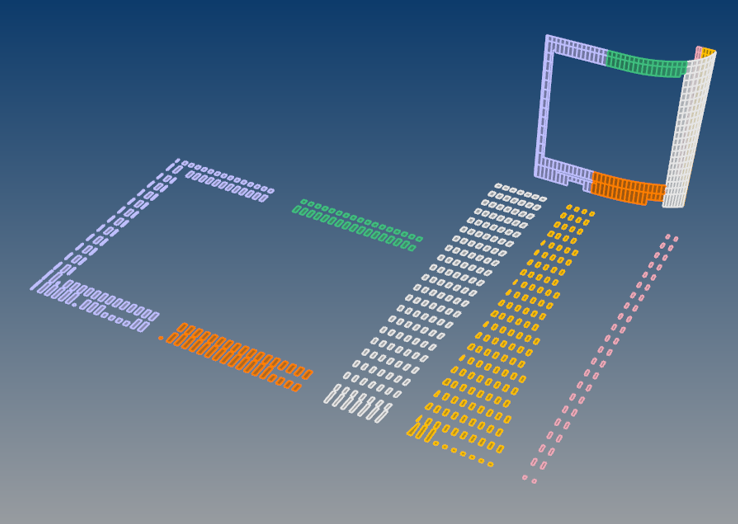

This is the glass geometry of the building at the completion. It is a square building with a three-dimensionally curved glass curtain wall. Due to rights reasons we are unable to show you actual photos of the building, but it has been completed in Tokyo.

In this project, our scope was to work on the glass curtain wall.

1.Smoothing the glass curtain wall façade

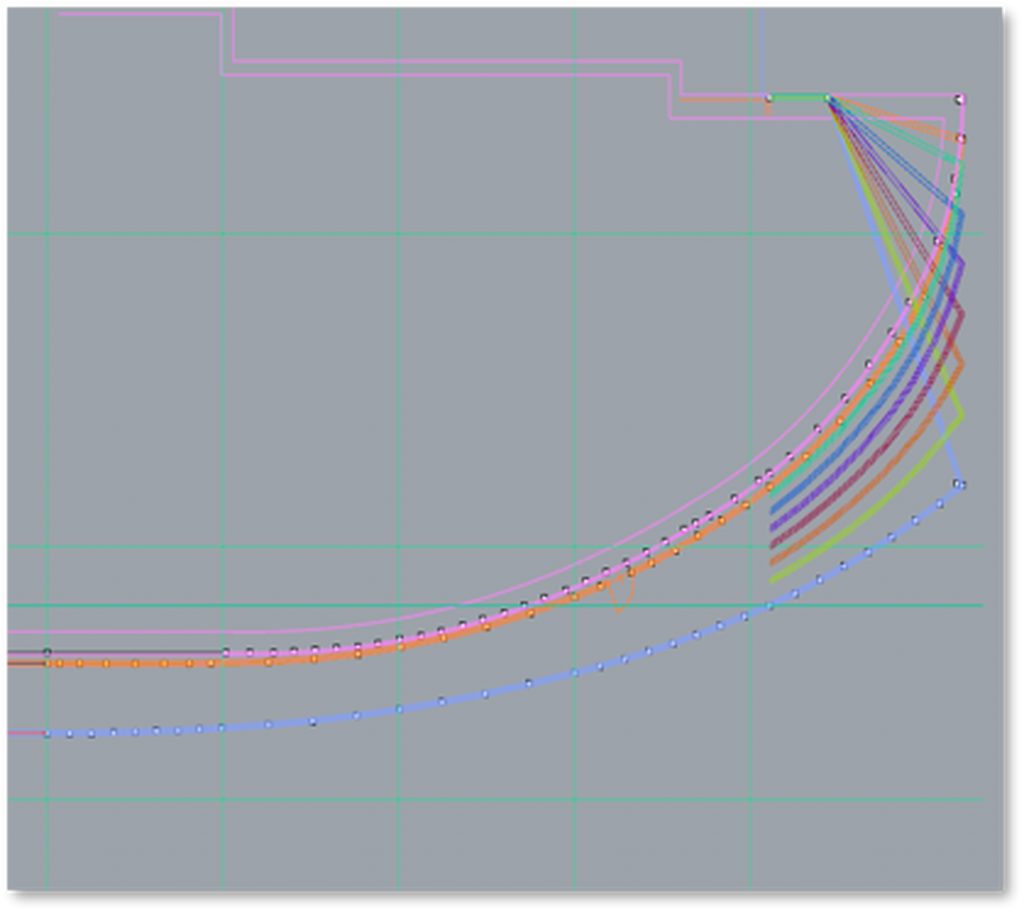

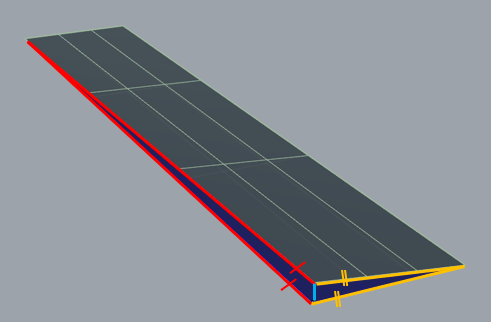

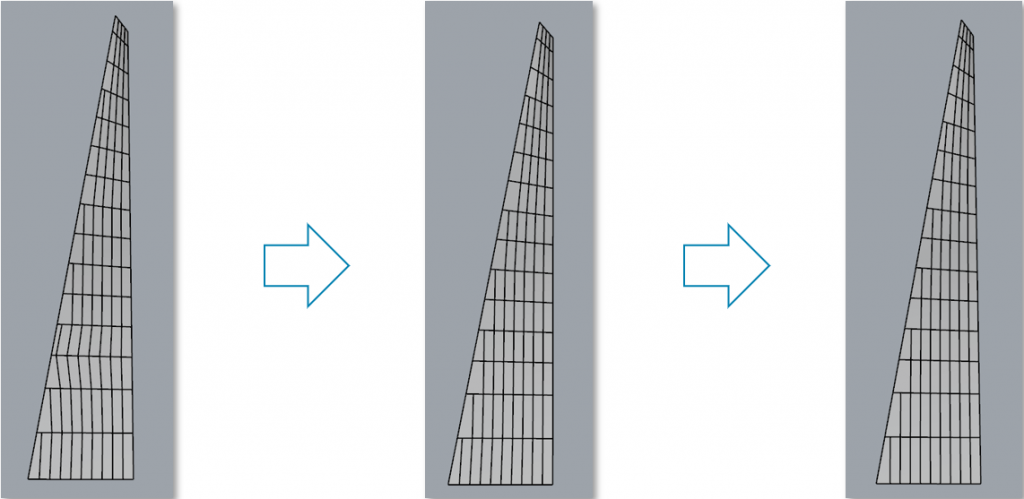

Firstly, through the client (a curtain wall company), we received 2D CAD data of this glass section at each floor (no 3D data in this case). When we went through the project data, we noticed that the façade geometries were in polylines(faceted surface). Since the intended design was to have a smooth curved surface, we started to translate the polylines into smooth curves.

Top right: Simple curved line, but the curvature is wobbly

Bottom left: Smooth curve, but the gap with the original curve is large.

Bottom right: Finally, the curve is divided into arcs to reduce the gap with the original curve.

By processing this to each curve and connecting them, a smooth surface was created.

2.Dividing the surface

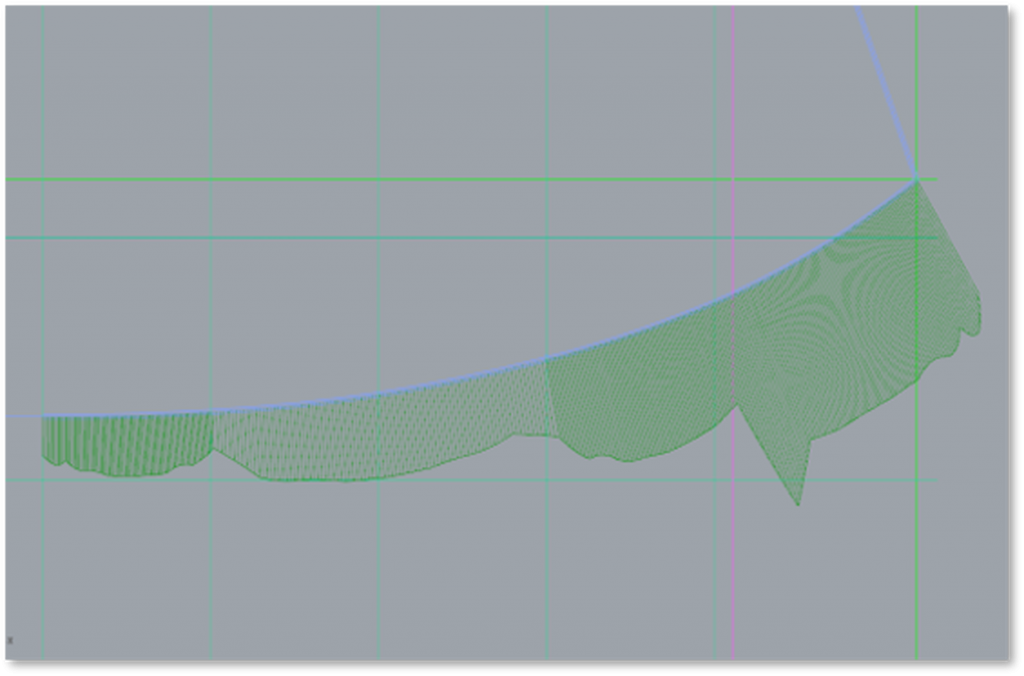

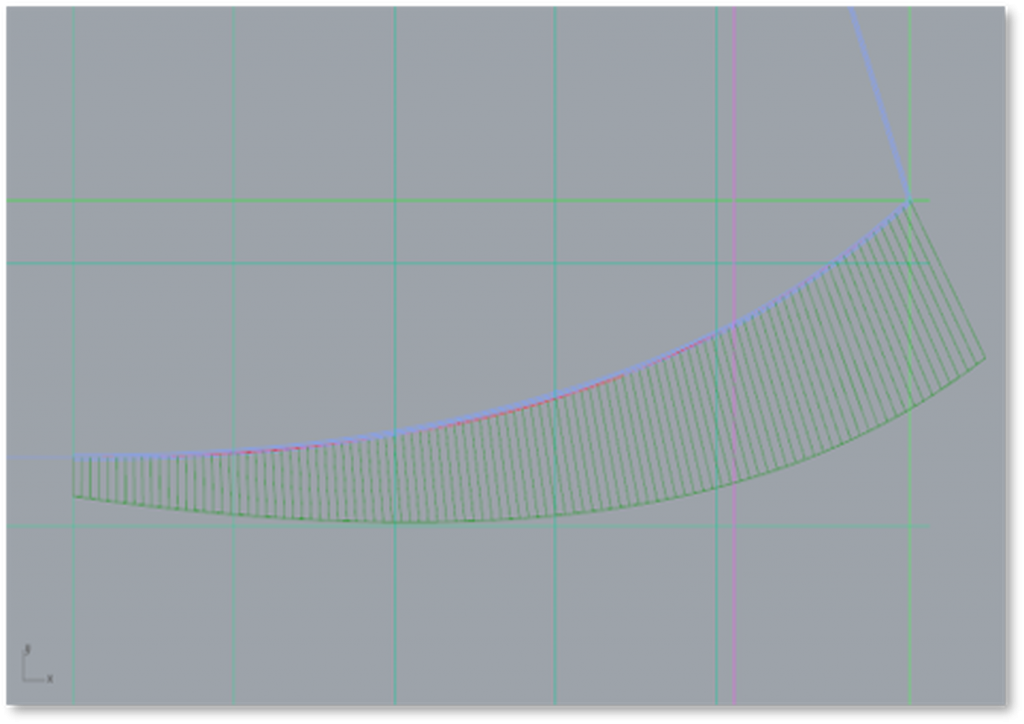

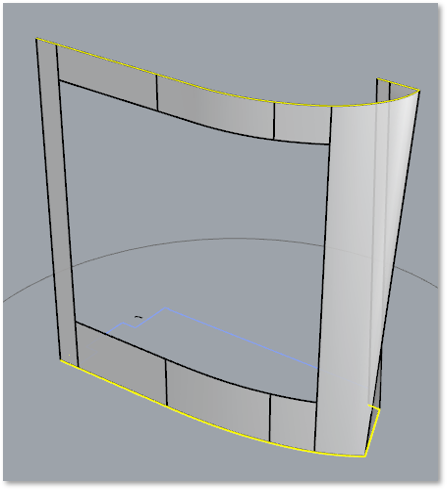

Through the initial stage, we were able to create the target shape of glass surface. However, the target shape could not be constructed with a single piece of glass, so we take the next step to figure out how to divide it.

The key here was a construction method called “Cold bending”. Rather than installing curved glass manufactured from a factory, the flat glass and frame are fixed in a bent state by applying force during the installation process. This eliminates the need to make each piece of glass curved at the factory, and thus reduces the cost.

As glass panels is not infinitely bendable at the normal temperature, we divided the glass surface so that the amount of deformation is in the range allowed without breaking.

To meet these requirements and creating an aesthetically pleasing façade grid, we had repeated discussions with the engineers, designer and the client.

Each piece of divided glass has a different shape. Each shape was categorized and exported in CAD so that the manufacturer could use them.

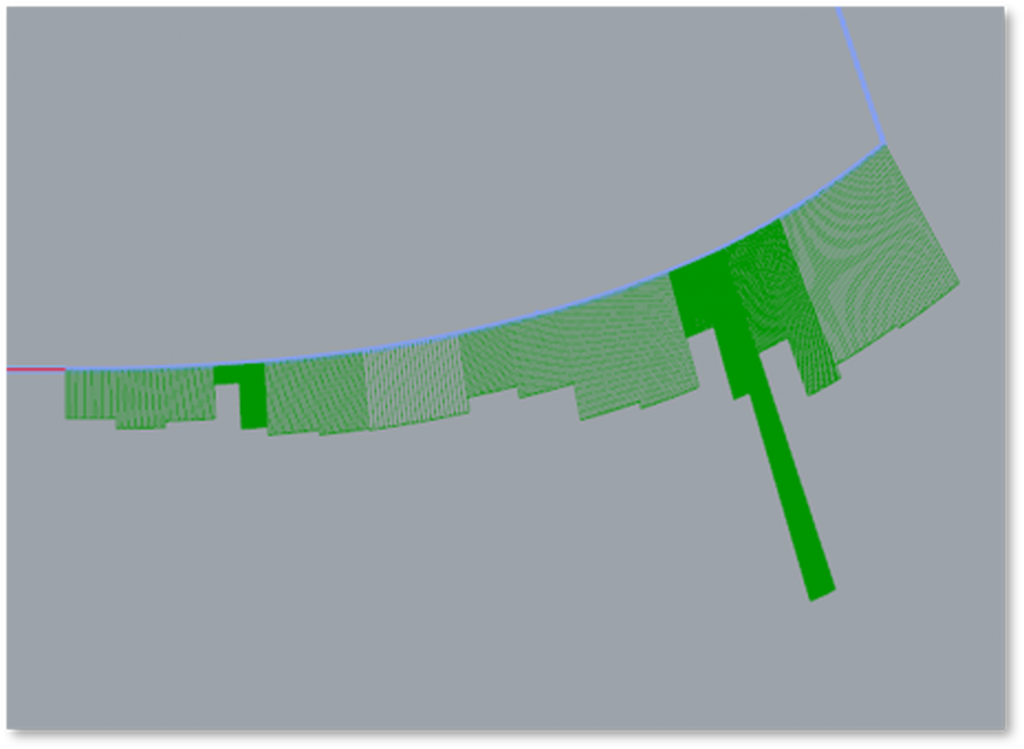

3. Modeling the framework and hardware to be installed

So far, we have managed to determine the shape of the glass. However, the building will not be able to stand on its own without a framework behind the glass to support it. Furthermore, in order to attach the glass to the steel frame, we also need the hardware to do so.

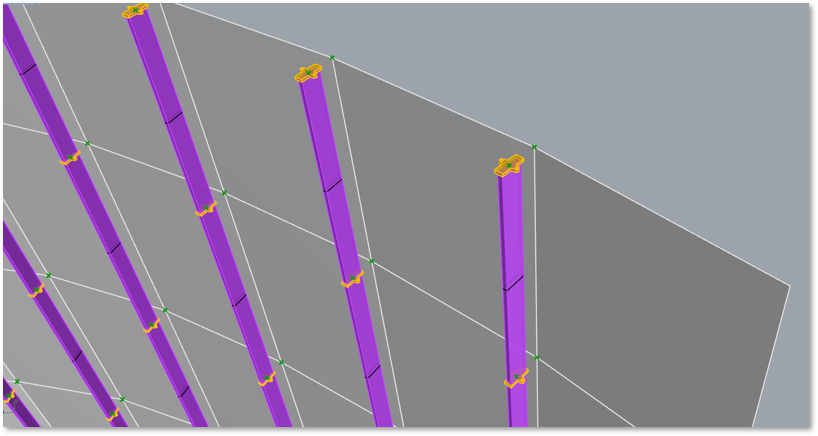

For this reason, I modeled the framework behind the glass (mullion).

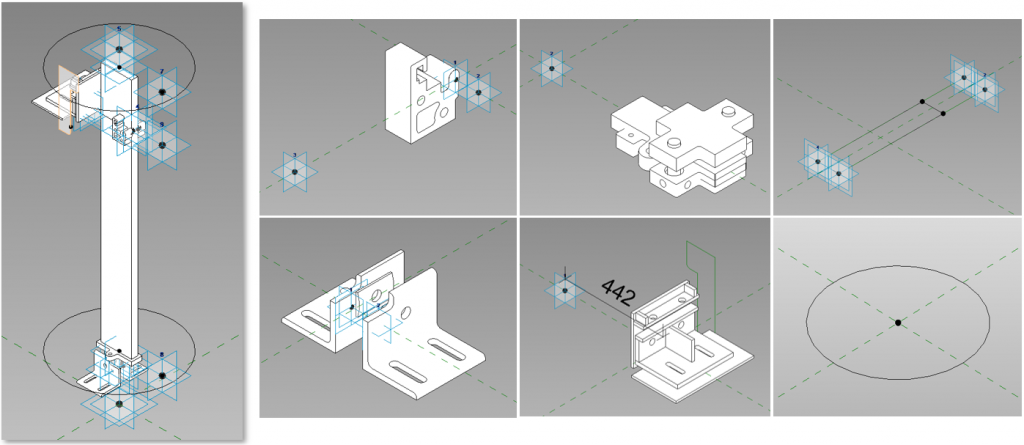

We also modeled the fixings for the glass to the frame. Even though the method to attach the glass is the same, the angle and shape of the hardware is slightly different because of the curved surface of the glass. It was hard to model everything one by one, so we applied the functions of the software to model them semi-automatically.

It is important to note that all these models are detailed 3D models that can be built as they are, with construction conditions incorporated. We are not creating 3D models to create a perspective drawing or to get a rough idea of the design, but to actually build it.

This is the essence of our work in this project.

4. Conclusion

I wrote this article using a single building as an example, but our outputs are mostly the same for all construction supporting projects.

To enable to build a complex shape, we understood the design intention and constructability issues then have enough discussion with designers and contractors until we deliver an adequate level of models. We also use software and programming to model even a single piece of hardware or a single screw, if necessary. This allows us to ensure the smooth construction process of the intended design.

In the construction industry, computers were firstly used in the design and engineering companies and have been used to create innovative designs. However, at the stage of constructing them, the capabilities of computers have not yet been fully utilized. Our strength lies in our ability to support everyone involved in the construction process with 3D models and information.

Translation: Yukie Takasu, Charlie Yoon